80/20 T-Slot Framing Fasteners: Internal vs. External

80/20 T-Slot Framing Fasteners: Internal vs. External

The sheer number of fastening options available for your T-slot builds can be a bit overwhelming, especially to the uninitiated. Hopefully, the information in this blog post will help you narrow down your choices and choose the fastening method best suited for your application.

The simplest way to categorize T-slot fasteners is to divide them into two categories: internal and external.

Generally speaking, internal fasteners are directly machined into the profiles to create a strong bond. They are easy to assemble and incorporate into your design. They usually don’t require additional hardware.

External fasteners mount directly on the outside of the T-slot profile and are easy to implement into a build. They require a little more effort than internal fasteners to assemble, but they generally offer more options for configuration.

Benefits of Internal Fasteners

- Recessed in T-slot

- Fewer parts required

- Easy to assemble

- Easy to incorporate

- Hidden connections available

- Hardware typically included*

- Usually won’t affect design area*

Benefits of External Fasteners

- Mount to outside of T-slot

- Easy to implement

- Easy to reconfigure

- Variable angle options

- Strengthen connection points

- Options to connect more than 2 profiles*

- Usually no machining required*

*There are some exceptions. For a more thorough breakdown of fastener features, consult the Internal/External Fastener Comparison Chart at the end of this post.

Internal Fastener Options

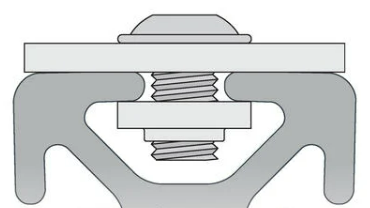

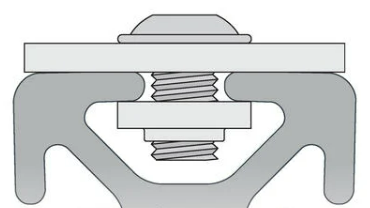

Anchor Fastener

The anchor fastener is made up of a socket head cap screw, cam, and T-nut. It is one of the strongest internal fastening methods, offering a long-lasting connection.

End Fastener

The end fastener is made up of a button head socket cap screw and wing clip. It provides a fixed 90-degree connection of moderate strength that is completely hidden.

Inside Corner Connector

The inside corner connector creates a strong 90-degree connection between two profiles. This connector requires no machining and no additional hardware, making a cost-effective fastening method.

Hidden Corner Connector

The hidden corner connector provides a 90-degree connection between two profiles, either inside of both or inside one and outside the other. It requires no machining but does require a hex wrench for tightening.

Butt Fastener

The butt fastener is made up of two cams and a bolt. It connects profiles end-to-end, providing a flush connection. This is one of the few internal connectors that requires machining.

Central Connector

The central connector is made up of a cam, conical set screw, spring, and T-stud. It is a strong and long-lasting (but adjustable) internal fastening method. This is one of the few internal connectors that requires machining.

Miter Connector

The miter connector creates a strong internal connection ranging from 90 to 180 degrees, reducing rotation between the profiles. This is one of the few internal connectors that requires machining.

External Fastener Options

Flat Joining Plate

The flat joining plate is an external fastening method that requires no machining services. It is a durable connection that can be repositioned and reused. The flat plate can provide infinite positioning along the profile T-slot, allowing for a large degree of adjustability.

Bracket/Gusset

Brackets are external fastening methods that create a 90-degree connection. They require no machining and can be easily adjusted along the profile T-slot. Gussets offer the same benefits as brackets, but their design provides a stronger connection.

3-Way Corner Connector

The 3-way corner connector is used to create a 90-degree corner connection between 3 profiles. Triangular and square configurations are available; both are functionally identical, but the square connectors provide a stronger connection.

45-Degree Support

The 45-degree support includes socket head cap screws, washers, and T-nuts. It is pre-machined with counterbores and a 45-degree miter angle on both ends to provide a clean, flush connection. The 45-degree support is often used to reinforce 90-degree connections.

Internal/External Fastener Comparison Chart

This chart provides a quick side-by-side comparison of the various T-slot fastening options.

| Part | No Machining | Hardware Included | Reconfigurable | Flush | More Than 2-Way Hub | Hidden | Infinite Positioning |

| Internal Fasteners | |||||||

| Anchor Fastener | X | X | X | X | |||

| End Fastener | X | X | X | X | |||

| Inside Corner Connector | X | X | X | ||||

| Hidden Corner Connector | X | X | X | X | X | ||

| Butt Fastener | X | X | |||||

| Central Connector | X | X | X | ||||

| Miter Connector | X | X | |||||

| External Fasteners | |||||||

| Flat Joining Plate | X | X | X | X | |||

| Bracket/Gusset | X | X | X | X | |||

| 3-Way Corner Connector | X | X | |||||

| 45-Degree Support | X | X | X | ||||

No Machining: This fastener is ready to use as-is and requires no additional machining.

Hardware Included: This fastener requires no additional hardware.

Reconfigurable: Once installed, this fastener may be easily adjusted.

Flush: This fastener provides a connection that is flush with the profile surface.

More Than 2-Way Hub: This fastener can be used to join 3 or more profiles in a single connection.

Hidden: This fastener is concealed within the profiles it is connecting.

Infinite Positioning: This fastener can literally be mounted anywhere along the length of a profile.

T-Slot Fasteners for Any Framing Application

Bear in mind that, in most cases, there is no “one right way” or “one right answer” when it comes to choosing a fastening method for your T-slot build. It all boils down to circumstance, design, purpose, and personal preference. If load-bearing is a concern, the Fastener Application Test in 80/20's Product Catalog can help you with your decision.

If you’re looking for more information on choosing the right fasteners for your application, this video from 80/20’s How to Design series will help you narrow down your choices.