Designed & Machined In-House

Integrated Solutions

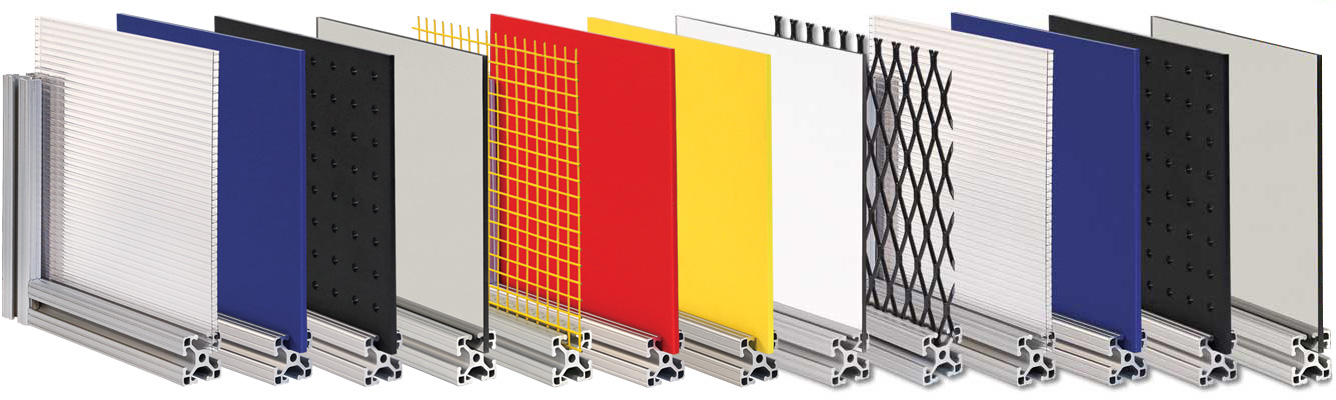

One of the many benefits with most of these stock panels, plates and wire mesh - they are intended for use specifically with aluminum profiles by integrating into the T-slot channel. This enables easy mounting as well as additional stability. And you'll find a panel, mesh, or plate to fit your requirements; from abrasion, weather or heat resistance, to optical clarity, we can accommodate.

Streamlined Services

Unlike most other providers, we machine our panel in-house saving you valuable time and money. You'll get your project fast and to your exact requirements. 80/20 machines are equipped with the technology to send your design files directly to the machine, ensuring accuracy and reducing turnaround times.

What Are Your Options?

Panel Selector

With over 100 in-stock materials to choose from, find the perfect panel for your project. Get started with the Panel Selector. Pick out the material, thickness, color, shape and size to suit your needs.

Product SelectorVariety of Machining

- Cut to Size

- Custom Designs

- Engraving

- Lettering

- Notching

- Perforating

- Recessing

- Much More!

80/20 panels, wire mesh and aluminum plates are sold on a square foot or square meter basis.

This means that with 80/20 you only pay for product that you use.

From Quoting to Completion

Before you even order your plastic panel, aluminum plate, or wire mesh, we're here to help you get the product you need for your specific project. This begins in the quoting stage, where your Design Technician can assist you in picking your panel and providing a quote for both the material and machining services.

We have the equipment to take your design and create the custom shape, access point, door, or barrier your project may require. The results of this extensive in-house shop are finalized materials that are seamlessly incorporated into your application.

Quality at a High Level

All of this is accomplished at the high level of quality we hold ourselves accountable to in all of our products and services. Your order will undergo multiple quality checks, from the design stage all the way to the finalized product. Each item is inspected before and after machining and is packaged to provide damage-free delivery.

The packing process includes the use of foam, shrink-wrap, bands, and high pressure packaging to make sure your panels, wire mesh, and plates don’t slide around during transit.