80/20 T-Slot Building System: The Original "Industrial Erector® Set"

80/20 T-Slot Building System: The Original "Industrial Erector® Set"

In the realm of industrial design and engineering, finding the right tools and components to build efficient and flexible structures can be a challenging endeavor. However, there exists a game-changing solution that has been revolutionizing the industry for decades: 80/20, often referred to as "the original industrial Erector Set."

Understanding the 80/20 Principle

The 80/20 Principle, also known as the Pareto Principle, was introduced in the early 20th century by Vilfredo Pareto, an Italian economist. Pareto observed that approximately 80% of the land in Italy was owned by just 20% of the population. Later, this principle was found to hold true in various other contexts, suggesting that a small percentage of inputs or efforts often account for a significant portion of outputs or results.

The 80/20 Principle has been applied in fields such as economics, business management, and productivity improvement. However, 80/20's impact on industrial design and engineering is particularly noteworthy. This principle can be seen as the foundation of the 80/20 T-slot aluminum framing system.

The Birth of 80/20: The Original Industrial Erector Set

In the early 1980s, Don Wood developed his groundbreaking structural framing system. His modular approach consisted of T-slot aluminum profiles, connectors, and accessories that allowed for the quick and easy assembly of elaborate and complex structures. Just as children used an Erector Set to build their ideas, industrial designers and engineers could now employ 80/20 as their own professional construction tool to assemble anything from workstations to automated machinery. In 1989, Don founded 80/20, Inc. with his two sons, Doug and John Wood.

Versatility and Customization

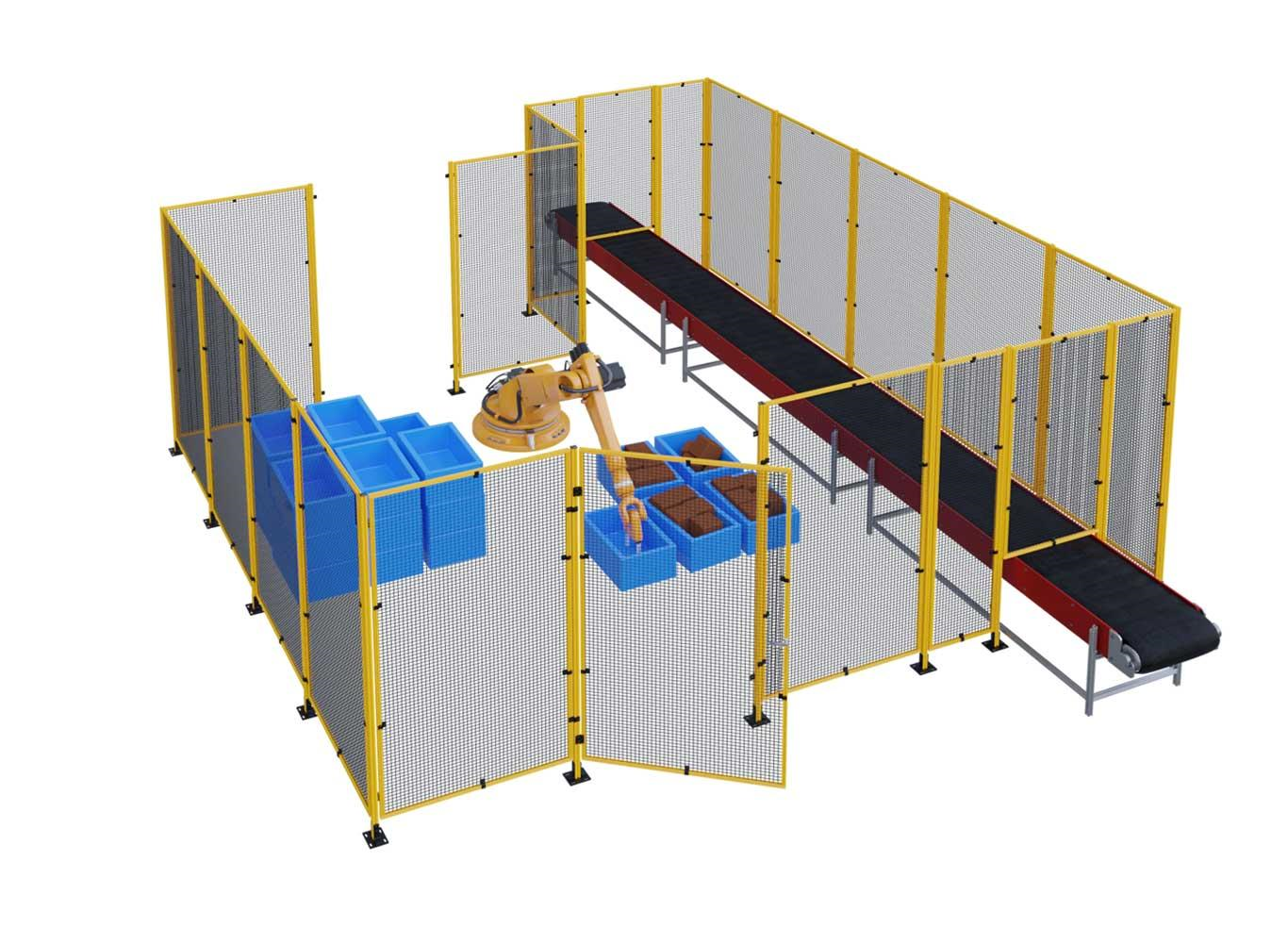

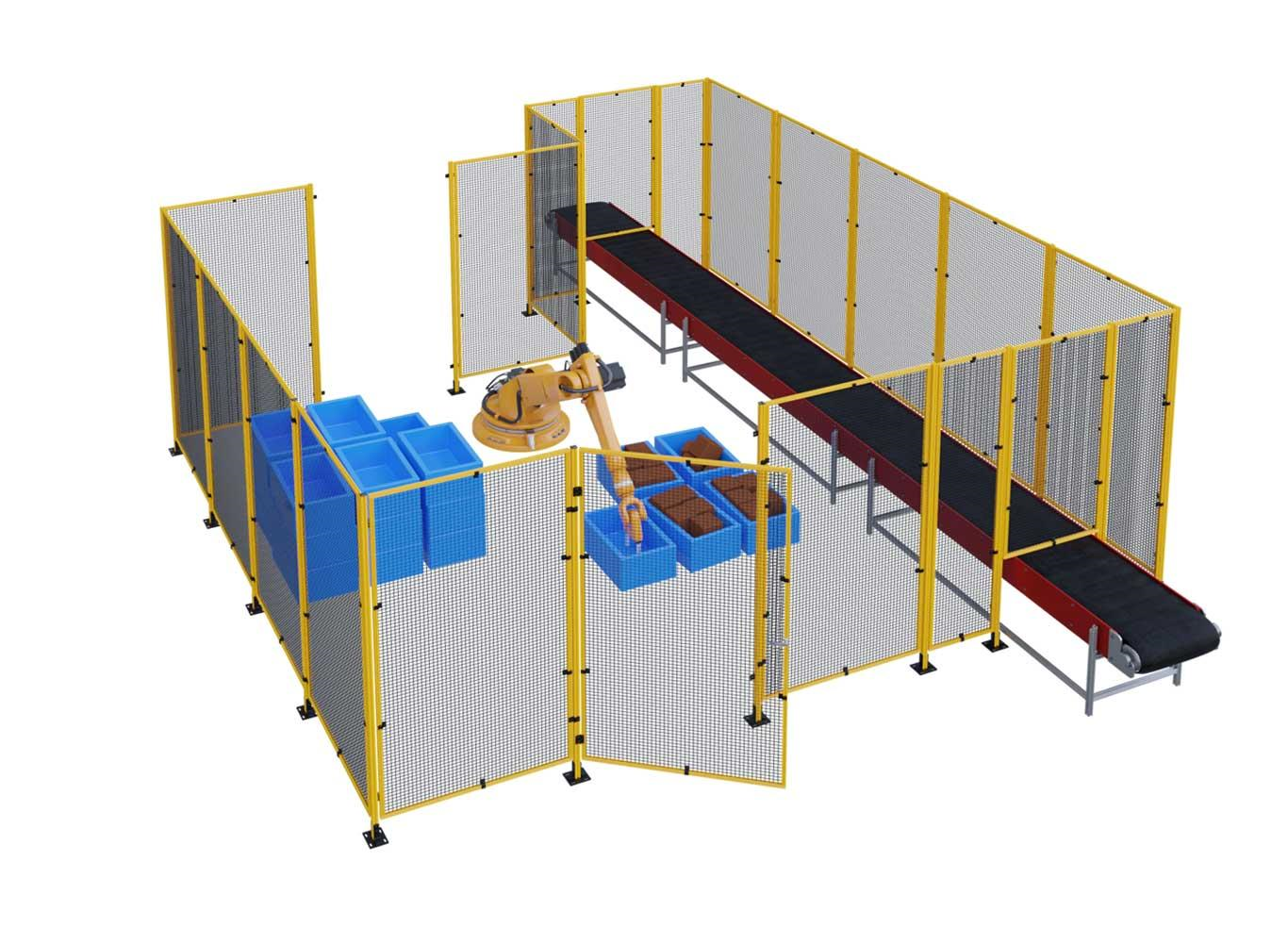

One of the key features of 80/20 is its unparalleled versatility. With a selection of 8,500+ profiles, connectors, fasteners, and accessories, the system enables designers and engineers to create highly customized structures for their specific needs. Whether it's a workstation, conveyor system, exhibit booth, or production line, the possibilities are virtually limitless.

The T-slot design of the aluminum profiles allows them to be easily assembled and reconfigured. The slots provide a secure and adjustable connection point for fasteners, making it simple to attach various components, such as panels, brackets, and other hardware. This flexibility and ease of customization ensure that 80/20 is adaptable to evolving requirements and allows for efficient use of resources.

Strength, Durability, and Aesthetic Appeal

Despite its lightweight nature, 80/20's T-slot aluminum profiles exhibit remarkable strength and durability. The high-quality aluminum construction offers excellent load-bearing capacity, making it suitable for both light-duty and heavy-duty applications. Additionally, the anodized or powder-coated finish provides protection against corrosion while enhancing the overall aesthetic appeal of the structures.

Efficiency and Cost-Effectiveness

The 80/20 system excels in optimizing efficiency and reducing costs. The modular nature of the system enables quick assembly and disassembly, facilitating easy modifications, reconfigurations, and repairs. This saves both time and money compared to traditional welded or bolted structures.

Furthermore, 80/20's longevity contributes to cost-effectiveness. Its durable materials and design ensure long-term usability, which means replacing parts far less frequently. This sustainability aspect aligns with the growing emphasis on eco-friendly practices across industries.

Applications Across Industries

The adaptability of the 80/20 system has led to its widespread adoption across a wide variety of industries. Manufacturers, engineers, and designers from automotive, architecture, industrial manufacturing, robotics, medical equipment, and countless other sectors have used 80/20 to create efficient and customized solutions. From assembly lines to cleanrooms, ergonomic workstations to safety enclosures, the possibilities for application are vast.